FUTURE OF FOOD INDUSTRY (My Published Article on Page NO.60

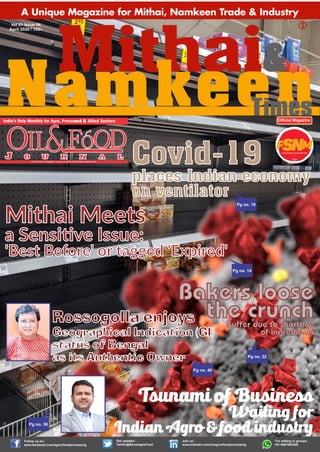

- 1. Vol 01 Issue 04 April 2020 100/- Ofcial Magazine Pg no. 10 Pg no. 14 Pg no. 40 Pg no. 22 Pg no. 38 Covid-19 places Indian economy on ventilator Bakers loose the crunchSuffer due to shortage of ingredients Mithai Meets a Sensi��e Issue: 'Best Before' or tagged 'Expired' Tsunami of Business Waiting for Indian Agro & food industry Rossogolla enjoys Geographical Indication (GI) status of Bengal as its Authentic Owner Follow us on: www.facebook.com/agronfoodprocessing Get updates : Twitter@BeveragesFood Join us : www.linkedin.com/in/agronfoodprocessing For adding in groups: +91-9867992299

- 2. 2 YOUR PERFECT TRAVEL PARTNER... Khaane Ka Swaad Badha De For any trade enquiry : +91 9415248245 |+91 9415231312 |+91 9918900795 andanifoodproducts@gmail.com Apoorv Andani : +91 9415248245 |+91 9415231312 |+91 9918900795 andanifoodproducts@gmail.com

- 3. 3

- 4. 4 ���������������D���������T��������D�����T.��TD. ������������������������������������������ ����������������������.���.�������������� ���������������������.��� Sri Dauji Mishthan Bhandar Pvt. Ltd. Sweets are manufacturers, retailers and exporters of Sweets, Namkeens and other related products since the year 1985.

- 5. 5 • OUTLATE : DEVIRAM SWEETS & RESTURANT Pratap Pura, X-ing, Agra Mob: 9897590391 • DEVIRAM SWEETS 1, Heritage Tower, Near Anjana Cinema, Agra Mob: 9897590387 • DEVIRAM SWEETS & FOOD PLAZA Shree ji Dham Complex, Shaheed Nagar, Police Chowki, Shamshadbad Road, Agra Mob: 9068801386 • DEVIRAM FOODS & HOTLES PVT. LTD Sikandra Bodla Road, Agra Phon : 0562-4031005 • DEVIRAM FOOD CIRCLE Dayal Bagh Road, Agra Mob: 9368239611 • HOTEL DEVIRAM PLACE Pratap Pura, X-ing, Agra Mob: 9068374091 Prepara�����

- 6. 6

- 7. 7 Pg 10 Pg 35 Pg 35 Pg 40 Pg 22 Pg 26 TABLE OF CONTENTS Covid-19 places Indian economy on ventilator Bakers loose the crunch Tsunami of Business Waiting for Indian Agro & food industry India: Pandemic Legal Intelligence Food Industry in COVID-19 times Mithai Meets a Sensitive Issue: ‘Best Before’ or tagged ‘Expired’ News Page no. 46 to 61 An Exclusive Interview of Dhiman Das

- 8. 8 Mithai Namkeen & A Unique Magazine for Mithai, Namkeen Trade & Industry Times The views expressed in this issue are those of the contributors and are not necessarily those of the magazine. Though every care has been taken to ensure the accuracy and authenticity of the infomation,"Mithai & Namkeen Times" is however not responsible for damages caused by misinterpretation of information expressed and implied within the pages of this issue. All disputes are to be referred to Mumbai Jurisdiction. Editor Manzar Aftab Naqvi Group Editor Firoz H. Naqvi firoz@advanceinfomedia.com Graphic Designer Naved H. Kazmi naved@advanceinfomedia.com Advertisement Executive Anjali Mane anjali@advanceinfomedia.com 8208074714/7400271714 Circulation Chandni Naqvi Chandni@advanceinfomedia.com Delhi Sayyed Shahnawaz +91-8375034558 General Manager Gyanendra Trivedi Gujarat Brijesh Mathuria +91-99245466999 Marketing & Circulation Office Distribution Agency Advance Info Media & Events 121,1st floor, Rassaz Multiplex, Station Road, Mira Road (E), Dist. Thane- 401107 Telefax : +91-22-28555069, Tell.: +91-22-28115068 Mob.: +91-9867992299 E-mail: info@advanceinfomedia.com sub@advanceinfomedia.com Vol 01, Issue 04, April 2020 Annual Subscription Rs.1350/- (Inclusive of Courier Charges) Add Rs. 50/- For Outstation Charges Overseas $80 By Air Mail Email:info@advanceinfomedia.com Single Copy Cost Rs. 100/- Printed, Published & Owned By Manzar Aftab Naqvi RNI No. MAHENG /2005/15987 Postal Regd. No. PLG /50/2020-2022 Regd. Office MashAd MultiCom P Ltd. 103, AmarJyot Apartments, Pooja Nagar, Mira Road (E) Dist Thane-401107(Mumbai) Printed At Rolleract Press Services A-84, Naraina Industrial Area Phase-1, New Delhi -110028 Consulting Editor Basma Hussain T he latest novel coronavirus pandemic may well be the result of our insatiable appetite and extraordinary capacity for the commodification of non-human life. And perhaps at the end of this crisis, we will be forced to truly consider what this means for the future. In the meanwhile, the govt. needs to take urgent and immediate steps to ensure that our agricultural commodity markets—and the millions of lives and livelihoods that depend on them—are secured and supported to the greatest extent possible. With COVID-19 coming into the picture, the Indian economy is going through a major slowdown, which was evident over the recent quarters even before the crisis struck. In the third quarter of the current financial year, the economy grew at a six-year low rate of 4.7%. With all these problems hitting the world of work from multiple directions, companies are finding it difficult to sustain in this environment. They are forced to take tough decisions such as cutting down the salaries, giving pink slips to employees and opting for other cost-cutting measures. The outbreak has presented new roadblocks for the Indian workforce and especially for the daily wage and contractual workers. Corona virus has disrupted the demand and supply chain across the country and with this disruption, it can be seen that the tourism, hospitality, and aviation sectors are among the worst affected sectors that are facing the maximum impact of the current crisis. Closing of cinema theatres and declining footfall in shopping complexes has affected the retail sector by impacting the consumption of both essential and discre- tionary items. As the consumption of any product or services goes down, it leads to an impact on the workforce. In the current scenario, with all the retailers closing down their services, the jobs of the employees are at a huge risk. The United Nations Conference on Trade and Development (UNCTAD), has suggest- ed that India’s trade impact due to the COVID-19 outbreak could be around US$ 348 million. India is among the top 15 countries that have been affected most as a result of manufacturing slowdown in China that is disrupting world trade. According to a survey by the Federation of Indian Chambers of Commerce & Industry (FICCI), the immediate impact of COVID-19 reveals that besides the direct impact on demand and supply of goods and services, businesses are also facing reduced cash flows due to slowing economic activity which in turn is having an impact on all pay- ments including to those for employees, interest, loan repayments and taxes. Job losses and salary cuts are likely in the high-risk services sector, including airlines, hotels, malls, multiplexes, restaurants, and retailers, which have seen a sharp fall in demand due to lockdowns across the country. If the current global and domestic eco- nomic slowdown persists, it will impact demand and realization. The International Labor Organization has called for urgent, large-scale and coordinat- ed measures across three pillars - protecting workers in the workplace, stimulating the economy and employment, and supporting jobs and incomes. According to a preliminary assessment report, nearly 25 million jobs could be lost worldwide due to the coronavirus pandemic, but an internationally coordinated policy response can help lower the impact on global unemployment. While on one hand, Indian employees are losing their jobs and receiving a salary cut, there is also an assumption that the majority of expats have gone back from India and they will take time to return. Different sectors such as automobile, banking and manu- facturing employ a large number of expats. Indian companies need expats for several industry verticals and job functions such as after-sales services, business development and market audits. There is an urgent need to take instant steps to not only contain the spread of the virus, but also to address the key pain areas of the industry which can help in minimizing the impact of the outbreak on the Indian economy and businesses. The Indian Government & RBI need to support the Indian industry and economy at this juncture. Since a large number of people will stand to lose their jobs especially in the retail, hos- pitality, travel, construction sector, the government can consider giving incentives for employers to keep the workers, while the coronavirus problem tides over. On March 24th, 2020 the Finance Minister extended the filing dates of ITR, GST, linking of PAN and Aadhar and other reliefs for the big and small enterprises. The finance ministry is already working on an economic package to mitigate the impact of coronavirus on the Indian economy. The government is taking necessary steps that will not damage the economy further but the damage that has been done in the previous few months will definitely last for a longer period of time. As the country is locked down for the coming three weeks, India Inc has to stretch themselves to sustain the situation and face the challenge. The Indian government has also urged employers to not cut jobs and salaries. Many CEOs and management teams are taking pay cuts to ensure their workforce does not have to bear the brunt. Editorial

- 9. 9

- 10. 10 Mithai & Namkeen Times Covid-19 places Indian economy on ventilator Indian industries , businesses, agriculture, food processing and supply side feel the tight pinch of recession leading to major dent on the economy causing unimaginable upheaval in people lives, especially the poor, the daily wagers, laborers; in fact everyone is distressed, in detention and distanced Outlook The rapid out- break of deadly Corona virus pandemic in the coun- try has not only led to a panic-like situation amongst the citizens, but has also hit Indian economy - which was al- ready reeling under a significant slow- down over the past few quarters. The medical rampant has presented fresh set of challenges for the country’s economy, causing severe disruptive impact on in- vestment and consumption demand. Country’s economy, which was growing at a six-year low rate of 4.7 per cent in the third quarter of the current fiscal, had strong hopes of recovery in the fourth quarter. However, the new Corona virus

- 11. 11Mithai & Namkeen Times epidemic has made the recovery extreme- ly difficult in the near to medium term. The outbreak has assembled new road- blocks for the Indian economy now, causing severe disruptive impact on both demand and supply side elements which has the potential to derail India’s growth story. Consumption is also getting impacted due to job losses and decline in income levels of people, particularly the daily wage earners due to slowing activity in several sectors including retail, construction, entertainment and others. With widespread fear and panic rapidly increasing among people across the country, overall con- fidence level of consumers has dropped significantly, leading to postponement of their purchasing decisions. Even the travel restric- tions imposed by Central gov- ernment to prevent the spread of Covid-19 in India have severely affected the transport sector. Large scale shutdown of factories and resulting delay in supply of goods from China has affected many Indian manufacturing sec- tors. Besides having a negative impact on imports of important raw materials, the slowdown in manufactur- ing activity in China and other markets of Asia, Europe and the US is impacting India’s exports to these countries as well, the report stated. Greater uncertainty about the future course and repercussion of Covid-19 has also made the financial market extreme- ly volatile. The Coronavirus pandemic has also pulled down India’s economic growth projections. Given the challeng- es that the businesses and people are facing currently, the Indian economy is most likely to experience a lower growth during the last quarter of the current fis- cal, the report claimed. It is also being said that in case the spread of Coronavirus continues, India’s growth may remain subdued in the first quar- ter of FY 20-21 as well. Rating agency Moody’s Investors Service has revised down its growth forecast for India to 5.3 per cent for 2020 from its earlier estimate of 5.4 per cent made in February. The agri and food industry experience the latest economic shock Covid-19 has brought things that never in our lives did we think would ever happen. In India, farmers are putting their cattle on an unorthodox diet: Some feed iceberg lettuce to buffalo. Others feed strawber- ries to cows. It’s not a treat. They can either feed their crops to animals or let them spoil. And other farmers are doing just that - dump- ing truck loads of fresh grapes to rot on compost heaps. The farmers cannot get their produce to consumers because of lockdowns that aim to stop the spread of corona virus. In India, as in many parts of the world, restrictions on population movement are wreaking havoc on farming and food sup- ply chains and raising concern of more widespread shortages and price spikes to come. Across the globe, millions of laborers cannot get to the fields for harvesting and planting. There are too few truck- ers to keep goods moving. Air freight ca- pacity for fresh produce has plummeted as planes are grounded. And there is a shortage of food containers for shipping because of a drop in voyages from Chi- na. In Florida, a lack of Mexican migrant laborers means watermelon and blueber- ry growers face the prospect of rotting crops. Similar shortages of workers in Europe mean vegetable farms are missing the window to plant. Such sprawling food production and dis- tribution shocks illustrate the pandemic’s seemingly boundless capacity to suffo- cate economies worldwide and upend even the most essential business and consumer markets. There has been limit- ed disruption so far to supplies of staple grains such as rice and wheat, although problems with planting and logistics are mounting. Indian farmersare feeding their straw- berries to cows because the local tourists that usually eat them are gone, as are the fruit vendors that once worked the streets of the nearby metropolis of Mumbai.An- other farmer is feeding lettuce to buffalo and is letting villagers take more for their own cattle. The hotels and restaurants that normally buy lettuce are closed. Agriculture Since it is the backbone of the country and part of government announced essential category, the impact is likely to be low on both primary agricultural production and usage of agri-inputs like seeds, pesticides and fertilizers. Migratory labour movement for harvest- ing wheat, paddy, pulses etc. should be allowed for the ongoing Rabi season. In- sulating the rural food production areas in the coming weeks will hold a great an- swer to the macro impact of COVID-19 on Indian food sector as well as larger economy. . Food retail Several state governments have already allowed free movement of fruits, vege- tables, milk etc. Due to fake propaganda, poultry sector (eggs and chicken) is heav- ily impacted. Fresh meat, seafood has erratic supply chain as there is no clarity from state governments on retail shops. Brick and mortar grocery retail chains and shops are operating normally but shortage of staff is impacting operations. It is expected that prolonged lockdown will result in increased demand for food supplies. Online food grocery platforms are heavily impacted due to unclear po- lice restrictions and stoppage of vehi- cles4. Last mile delivery platforms are impacted too. States are working out pol- icies for food movement which are likely to ease the situation. Food processing All food based industries are allowed to function normally. There are few issues on interstate movement of skilled and semi skilled labour that needs to be sort- ed out. Raw material supplies are not im- pacted as of now and the measures taken by central government should ease supply chain issues. Factories should adjust to working with less labour force and over- time to meet demand. Domestic market based players should not have a problem. Food exports: Major destinations like the U.S. Europe, China will grapple with COVID-19 for the next 6 months and In- dian export based companies will be im- pacted due to low consumer demand and port hurdles. Partial diversion of export inventories to domestic market will help the players in the interim. Farm gate pric- es for export oriented commodities like seafood, mango, and grapes are crashing and this will impact future crop availabil-

- 12. 12 Mithai & Namkeen Times ity. Consumer supplies of cereals, pulses, fruits, and vegetables, dairy are largely secured as they are part of essential list of government. Interstate food move- ments are erratic and may impact prices in next few weeks. State policies on trans- port, e-commerce will decide future price movements. Edible oil prices are expected to go down in the short term due to global down turn in demand. Import dependent agro chem- icals, and fertilizer sector may see some volatility in the long term. Industrial sup- ply of agri-commodities are expected to be normal in short term but long term im- pact will be known only after three to four months, Majority of food processing units are not impacted except for ice cream and Quick Service Restaurants (QSR) based food supplies etc. So it is the government duty to ensure prioritization of food catego- ries under essential list. Rabi season harvest for wheat, rice and pulses may get impacted due to restric- tion and/or unavailability on inters state movement of labour force and agri ma- chinery. Recent announcements from State and Central governments should ease the situation in the coming week. Stranded migrant laborers The potential impact of planting and har- vest disruptions is most acute in poorer countries with big populations, said Ab- dolrezaAbbassian, a senior economist at the United Nations Food and Agriculture Organization (FAO). India - the world’s second-most populous country, where a majority of the popula- tion is involved in agriculture - is among the most vulnerable nations to the disrup- tions. PM Modi imposed a 21-day lockdown with just a few hours notice on March 25, leaving many of its 120 million migrant laborers struggling to get home and with no money for rent, food or transport. The country’s northern grain bowl relies on labor from eastern parts of the country, but workers have left the farms because of the lockdown. So who is going to fill the grain bags and bring the produce to market, and transport it to mills? Supply problems in one place are quick- ly felt on the other side of the world. In Canada, imports of specialty Indian vege- tables such as onions, okra, and eggplant have dropped by as much as 80% in the past two weeks as air cargo space dwin- dled. In addition to the trucking problems, a sharp decline in air traffic has cut deeply into capacity to move fresh produce long distances. United States fruit importers rely heavily on commercial flights to shift papayas and other produce from Brazil. Now they is buying more from Mexico and Guatemala, where goods can still be shipped by trucks. In Europe, it’s even worse, because they don’t have a Mexico-like source for pa- payas. U.S. and Canadian exporters are grappling with a shortage of refrigerated containers to supply goods, as voyages of container ships from China to the West Coast are down by a quarter due to re- duced demand because of lockdowns. A different kind of crisis The emerging supply-chain disruptions are much different than the food cri- ses of 2007-2008 and 2010-2012, when droughts in grain-producing nations caused shortages that led to higher pric- es, unrest and riots in several countries. Those price spikes were driven in part by state hoarding of rice and other staples. Now, staple grain supplies are relatively plentiful and global prices have been low for years as farmers in the United States, Brazil and in the Black Sea region have planted more and improved yields. Although there are signs that big import- ers such as Iraq and Egypt are boosting grains purchases amid rising food secu- rity concerns, other countries are boost- ing exports. Second-largest rice exporter

- 13. 13

- 14. Agro & Food Processing September 2019 Sanjeev Gupta Managing Director Kanchan Metals Pvt.Ltd 14 Mithai & Namkeen Times Thailand, for instance, is taking advan- tage of higher rice prices by increasing exports from stockpiles. Top rice exporter India, however, has stopped rice exports due to labor short- ages and logistics problems. Third-largest exporter Vietnam has also curbed exports. African nations - where many people spend more than half of their income on food - are among the most vulnerable to disruptions in staple food supplies. The continent is the fastest-growing consumer of rice, accounting for 35% of global imports and 30% of wheat im- ports. Sub-Saharan Africa alone is the third-largest rice consuming region, yet holds the smallest grain inventories - rel- ative to demand - of all regions, because of tight government budgets and limited storage. While the earlier food crises involved supply shocks, today the problem is get- ting plentiful supplies to the people who need it - many of whom have suddenly lost their income. “It is a whole different animal, you don’t have labor, you don’t have trucks to move the food, and you don’t have money to buy the food.” Logistics a challenge to delivery of products Indian companies, which are grappling with the disruption in manufacturing caused by the nationwide lockdown, will have to contend with another big chal- lenge for weeks and months, the delivery of products including food and medicines. PM Modi has indicated that the lockdown will be eased gradually from mid-April, but the domestic industry is staring at a huge shortage of truck drivers and load- ers, with many workers having returned to their hometowns after the lockdown was announced.

- 15. 15

- 16. Mithai & Namkeen Times 16 Mithai & Namkeen Times A BREAKTHROUGH IN PACKAGING TECHNOLOGY GT-5S 19 x 15 cm • Sturdy, versatile & compact • Designed to run Pillow, Gusseted and Flat-bottom bags • Quick change forming Tubes & Films rolls • Speed up to 100 bags per minute • Multi-axis (Trio) Motion Controls • Panasonic Servo Motors • No electrical or mechanical proprietary parts • Operator friendly Program and Controls • In-built temp couples • Touch Control panel • Electric reel including End of Film Alarm • Tool-free adjustment • Stainless steel Construction Made to perform, built to last, GT-5S is the next generation high speed continuous motion bagger from Packit. GT-5S is the logical choice when high speed packaging is required! Extremely sturdy & reliable Enjoy quality assurance Involves low maintenance Comes with service guarantee Plot 41 G DLF Industrial Area Phase 1, Faridabad 121003 IN T: +91 129 2259169 E: info@vspackit.com W: http://www.vspackit.com For enquiries, call +91 9811103573 or visit www.vspackit.com About 40% of drivers are not available for trucks in the industry at present. This may not change dramatically. If people have crossed borders, it is virtually im- possible to get them back,” according to Associated Chambers of Commerce and Industry of India (Assocham). The second thing to consider is the sup- ply side that many of the companies don’t have inventories and fast-moving con- sumer goods companies are working at 40% of capacity because they are not get- ting employees and restrictions on border movement are adding to the difficulties. Even after workers return, the fear of infections due to the covid-19 outbreak would likely involve a mammoth effort at rebuilding confidence and educating them about hygiene practices, including the use of sanitizers and face masks, besides the importance of washing hands frequently. The foundation of the industry will have to be rebuilt through the use of things such as a pallet—a flat wooden container structure that can be used by forklifts—to minimize points of touch. Given the pre- vailing and dynamic situation, it is inev- itable that some disruptions are likely to take place when a fine balance has to be maintained between deliveries of essen- tial products, even as norms, such as re- stricted movement and social distancing, is followed by the frontline warriors. Inter-state and local truck movement has been severely impacted together with the challenge of shortage of manpower in factories. Localized solutions with help from communities around the factories are being explored and implemented. It is believed that it will take a few more days for the entire ecosystem and processes to be streamlined for movement of essential goods. ITC, which makes Aashirvaad atta (wheat flour), Sunfeast Biscuits and Savlon anti- septic liquid, soaps, and sanitizers, said it was trying to work with local authorities to ensure the continuity of services with a minimum number of people. Online grocery chain Grofers said though it has now resumed operations in 100% of cit- ies, it continues to cap fresh orders once it

- 17. 17

- 18. Mithai & Namkeen Times 18 reaches maximum capacity for servicing them in a given location. India’s packaged industry has been hit hard India’s packaged industry has been hit hard by the 21 days lockdown with most factories closed and their supply chain disrupted making the distribution effec- tively being suspended nationwide. Food manufacturers do not have an au- tomatic right to stay open but have had to apply for specific exemption from the state, municipal and national regulators. And while many manufacturers have lodged application with the regulators, bureaucratic procedure are causing long delays. Once the food manufacturer get the per- mission to run the factory, they need one for transportation of products and then to transport in night and then to cross borders. Then outlets like MacDonald’s, Dominos, subway, KFC, Pizza Hut, and Starbucksneed different set of permis- sions from different authorities. However, if the red tape is cleared, food manufacturers face an even big hurdle- the unavailability of labor as hundreds of workers left Indian cities and major industrial centers for their home towns to sit out the lockdown. A lack of earnings and scarcity of food supplies during the lockdown were the main reasons for many moving. Accord- ing to Confederation of Indian Food Trade & Industry (CIFTI), even the fami- lies that live near the plants are not report- ing to due to lack of transport facilities. Also, the governments’ instruction that companies should pay full wedges to all workers during lockdown has eroded the incentive for them at work-even though that order is not legally enforceable. Food imports into India have also come under pressure, as ports are open but they are not functional. Private container freight stations and testing labs are non functional, clearing agents and custom of- ficial are not coming as there is no means of transport to the ports. Furthermore trucks are also not operat- ing with many haulers simply stopping driving after lockdown. This has dam- aged all products requiring refrigeration. Meanwhile most food stores have empty shelves, with only milk, bread and eggs are being delivered as usual.As a result of these problems some food manufacturers are waiting for the lockdown to end. An ominous situation for crops and farm-to-food chain The government has sought to reassure an anxious public that the country has mul- tiple times the required reserve of food grains to tide over the crisis. There have also been urgent calls for both central and state governments to ensure that the pub- lic distribution system — PDS — is fully supported to safeguard food security, es- pecially for the millions of poor families who will be disproportionately affected by the massive closures. A few states have responded quickly, announcing a range of measures includ- ing food rations and mid-day meals to provide basic support to those who will struggle daily to survive. Their imple- mentation will be absolutely critical. India’s huge buffer stock, however, will not offer any protection to those farmers who are currently supplying fresh pro- duce markets and those who are depend- ing on returns from the rabiharvest that looms ahead. We already know that the widespread fear around the possible animal transmission of the virus, coupled with reported cases of bird flu, has led to a meltdown in the Indian poultry industry, with a steep de- cline in prices over the last two months. This will, in all likelihood, also depress the feed market and its constitutive com- modities, especially the price of maize. For farmers in eastern Bihar, whose ra-

- 19. Mithai & Namkeen Times 19

- 20. Mithai & Namkeen Times 20 bimaize starts coming into the market in large volumes in April, this is ominous news. No buyers in mandis Major wholesale horticultural produce markets are already contracting. Potato traders in Azadpur Mandi said that they are trying to shut shop over the next two days and have asked farmers to stop send- ing trucks and to store whatever they can at their end. Meanwhile, they are trying to sell the stocks from some 190 trucks that have been standing in the mandi yard. As it happens, this is the season for kac- chapotato, which once harvested cannot be stored. But there is no public transport and few buyers. Wherever possible, for seasonal produce such as mosambi (sweet lime) and oranges, traders are packing them in cold storages. Credit rotations, on which these markets run, are already breaking down. Both farmers and traders are uncertain about the status of the government’s wheat procurement operations for the upcoming season. As a trader recalled to- day: notebandi(demonetisation) hit us at the peak of the kharifmarketing season in 2016, and now coronavirus has hit just as the rabiharvest is about to arrive. The im- pact is likely to be severe, especially be- cause it comes on the back of long-term agrarian distress. This calls for urgent action and innova- tion. First, farmers (landed and landless) and agricultural laborers need to be in- cluded in the economic relief and income support measures that the centre and state governments are working out. Both the Centre and the states have developed Direct Benefit Transfer (DBT)/income support platforms for agriculturalists, and these must now be utilized. At the same time, it is also critical for us to think quickly and collectively about how we can support and protect our vast, interconnected agricultural production and marketing system so that it can keep moving as fairly and as safely as possible in order for India to attempt to stand still. What should public procurement look like during a pandemic? When wheat procurement starts next month, we will need to streamline and manage the flow of arrivals into mandis and procurement centres in line with protocols for social distancing. For those familiar with these marketplaces, this may sound highly un- realistic. Major mandis are usually packed to the brim and overflowing during peak season and the pile ups are especially high when- ever there is uncertainty about market clo- sures and public procurement windows. But states such as Madhya Pradesh have used SMS-based pre-registration systems fairly successfully in the past to try to reg- ulate arrivals and manage logistics and these will now need to be deployed and further strengthened. Communication needs to be very clear and consistent so that farmers do not flood market sites for fear of closure. Payments will also need to be processed quickly. Each step of exchange and transfer – sam- pling, auctions, weighing and payment – can be reviewed to minimize crowding and contact. In the upcoming season, a quick plan ahead is neededto better uti- lize and enhance storage and warehous- ing facilities and ensure more transparent inventory management so that farmers, in particular, may benefit from such action. This means getting credit and financ- ing systems in place and working out strategies to urgently step up support to well-functioning Farmer Producer Orga- nizations (FPOs). It is important to ensure that transportation networks enable the timely and safe movement of food. A significant proportion of agricultural produce, especially fresh produce, moves daily—locally and regionally—via public transport. If these systems remain closed for long, alternative and accessible trans- portation options will need to be made available. Strengthen local food systems Finally, there is need to focus on both public and private food distribution sys- tems and ensure that they work as equi- tably as possible. Historically, in times of crisis, food markets become explosive sites for the expression of public fear, an- ger and aggression. Reports of widespread consumer panic and the stockpiling of food and house- hold provisions from New York to New Delhi tell us that this time is unlikely to be different. But, at least in some places, there is also much-needed recognition of the essential services that grocers provide every day. For instance, the governments of Minne- sota andVermont in the United States have classified grocery clerks as ‘emergency workers’, entitling them to state-funded childcare services and other benefits so that they can continue to serve in stores. We need to think about our own vast, largely informal networks of traders, wholesalers and retailers and take con- crete steps to support them as they keep working during shutdowns. This period of social distancing and bor- der closures may also be precisely the time to strengthen local food systems, reducing the distance between production and consumption wherever feasible.

- 21. 21

- 22. Mithai & Namkeen Times22 Bakers loose the crunch Suffer due to shortage of ingredients T he supply of bread has become scarce as many bakers have shut operations owing to the shortage of labour and disruption in logistics facili- ties due to the lockdown. As a result, roller flour millers have seen a drastic decline in sales of refined flour or maida, a widely used ingredient in the manufacture of bakery products such as bread and biscuits. There has been a substantial drop in sales of maida over the past few days. Sales are down by about 90 per cent as the demand from bakeries has come down drastically, according to All India Roller Flour Mill- ers Association. While the m a - jority of the small bakers have shut op- erations, large industrial bakers such as Modern Foods, Britannia and Kitty In- dustries, among others, are operating at a lower capacity. Shortage of labour and raw material, mainly used in packing, and transporta- tion issues, have forced small factories scale down production capacity by 60 per cent. Like Kitty Industries Pvt Ltd, in Ludhiana, which sells bakery products under the Kitty brand across North India which is at the verge of closedown. Also, the lockdown has impacted demand from both institutions and the retail seg- ment. As a result, many factories have stopped manufacturing all other products such as unbranded biscuits, bun, pav and pizza base, except bread. The Indian bak- ery sector is largely dominated by smaller units in the unorganized sector.According to market research firm IMARC, the size of the bakery market, which was estimat- ed to be $6 billion in 2017, is expected to grow to $11 billion by 2023. According to the All India Bread Manu- facturers Association, the smaller bakers in the unorganized segment are the worst affected. Though institutional demand has been hit, there have been instances of increased demand from some retail consumers. There have been instances of people buying more loaves of bread than normal as supplies have dwindled. With transportation of goods becoming a challenge, the shortage in supply of bread and related products is being felt in sev- eral locations across the country. Though the bakery sector falls under essential food category, many bakers have not re- sumed operations despite easing of curbs. Beekays, a large baker in Bengaluru which manufactures about 150 products, has shut down operations for about a week due to the shortage of labour and raw material. The company, which is highly dependent on migrant labour, has not seen them returning after they went to their villages to celebrate Ugadi. Many of the members of the Karnataka Wrapped Bread Manufacturers Association have either stopped operations or are running at a lower capacity. The availability of ingredients required by bread manufacturers has also been impacted since supply chains were inter- rupted soon after the lockdown was an- nounced. Essential ingredients like yeast have been hard to find as well, because the government does not list it as an es- sential commodity. Without adequate supplies of yeast, bread makers would find it impossible to run their operations. In the Kolkata metropolitan area, there are approximately 1,000 bakeries, of which only half are open at present. However, with difficulties in procuring ingredients and labour shortages, they are struggling to continue operations. Bread factory owners who are members of the Baker’s Association have not in- creased the prices of their breads; they had heard reports of local shops selling them at inflated costs. Bread factories already have commission margins in place for shops to whom they supply. Shops should not take advantage of people during this situation and sell breads at higher costs.

- 23. 23

- 24. Mithai & Namkeen Times 24 This is criminal Not enough grains to manufacture atta, maida, sooji hence shortage of baking products The food processing industry is bearing the brunt of the shortage of raw materi- als to manufacture essential commodities such as atta (flour), maida (refined flour) and other products even as both the cen- tral and state governments scramble to provide food supplies including grocery items, vegetables and fruits during the 21-day lockdown. The lack of raw material supply is, how- ever, not the only hurdle being faced by the food processing sector — there has been a lack of labour availability at both procurement and disposal levels along with the choking up of road transport at various state borders due to a shortage of curfew passes. As a result, stakeholders in the industry say production has drastically dropped. A wheat trader and flour mill owner in Bi- har said that they used to process around 200 tons of wheat every day to manufac- ture atta and maida. That has gone down by at least 60 per cent due to a lack of raw material like wheat, they used to pro- cure wheat from Uttar Pradesh but the trucks are stuck at the state borders and no one knows whether they would be able to reach or not. Though the state govern- ment is cooperating, the supply of pack- aging bags is also restricted due to the lockdown and millers require at least 4,000 bags to pack- age the items manufac- tured here at the factory but they are left with just a few dozen now. Commodities manufactured by the food processing industry such as atta, maida, sooji, besan and bread fall under the fast-moving consumer goods (FMCG) category, which are products that are sold at a low cost and are perishable. It is for this very reason that these industries don’t stock up enough products under any sit- uation as their very nature means they cannot stay on shelves for a long period of time. Wheat stock for the time being is a max- imum of three to four days to a week to make flour and other products as the wheat can’t be consumed as it is. The annual wheat season has ended and new crop are to be procured from states. But that has stopped completely due to the lockdown. Also thereare no labour and truck drivers at all points of production and supply due to a lack of curfew passes. The mills and even the FCI (Food Corporation of India) have contractual labour that is also miss- ing due to curfew passes unavailability. FCI sells wheat just once a week under the open market sale scheme, leaving the mills with little opportunity to procure it during the lockdown. According to official data, the govern- ment currently has a total of 58.49 million tons of food grain in the FCI go downs, of which rice constitutes 30.97 million tonnes and wheat 27.52 million tons. Pulse processing industry stumbles The pulse processing industry too is struggling to procure raw material and manufacture products such as namkeens, bakery items, ready-to-eat snacks and besan, all of which come un- der essential commodities. Around 90 per cent of pulse processing in India is done by the private sector, which is now struggling to meet the supply according to the Pulse Association. The Ministry of Food Processing Indus- tries said that the situation will hit urban customers. The government’s prima- ry objective is to provide the poor with grains and pulses through the ration and PDS route but the supply and labour dis- ruption to the food processing industry is set to hurt urban consumers in the coming times. MOFPI is appealing to the states’ Consumer Affairs, Food and Public Dis- tribution to provide grains and pulses to the food grain industries but it will take some time to implement the order at the last mile.” The government should identify a sub- stantial number of mills in every state and provide them with raw materials to man- ufacture products along with facilitating the supply of plastic bags. India’s big- gest cooperative marketing organization, NAFED, has unlocked 35 lakh tons of pulses, 18 lakh tons of gram and several other agricultural produce from its ware- house spread across the nation to boost the food supply chain. A large scale migration of labourers from cities to their villages, and transport is- sues in several states, had affected the food supply chain in the world’s second most populated country where over 1.3 billion are locked in their homes to pre- vent spread of the pandemic, COVID-19. The closure of grain markets, the plat- form for millions of farmers for selling their agriculture produce, multiplied trou- ble for the millers, edible oil producers and wholesalers. The Centre has already asked state governments to open the mandis (grain markets). In Madhya Pradesh, Andhra Pradesh and Telangana, grain markets are opera- tional. Maharashtra is going to follow. In Rajasthan due to the spread of the pandemic government is reviewing the situation. Overall the inputs coming from the states are a welcome sign for farmers. As laborers affect the supply chain, sup- plies of essential commodity items like atta (wheat flour) and besan (gram flour) are running out in some parts of the coun- try. Due to the lockdown only 25 per cent of dal (pulses) mills are operational. Sub- sequently the price of besan has increased in the market. NAFED has liquidated 2 lakh tons of pulses, raw pulses to the millers and trad- ers in the past few days. The government is on the job to resolve the issues arising out of the curfew like situation. The trad- ers are buying from NAFED, and will buy more once grain markets are operational.”

- 25. 25

- 26. Mithai & Namkeen Times26 Mithai Meets a Sensitive Issue: ‘Best Before’ or tagged ‘Expired’ F rom 1st June 2020 onwards, FS- SAI’s latest mandate is that, every local sweet shop should display the ‘Best before Date’ or ‘Date of Manufac- turing’ on loose or open mithai/sweets kept in the tray containers for sale at their outlets. The food regulator has expressed that the sweet shops could also mention the suggestive shelf life list in compliance with the new rules. It even suggested that sweet items like milk cake, rasgullas, ras- malai, rajbhog, kalakand and other milk- made sweets should be sold and consumed within two days of their manufacture. But this move by FSSAI has raised concerns amidst the sweets manufacturers in the industry and they have expressed their dismal about this decision. The mithai and namkeen industry in India has witnessed tremendous double-dig- it growth year-on-year. Today, it has achieved the milestone of one lakh crore turnover. India is the only country having more 500 varieties of sweets and mithai in the world. Its love for sweets is known in the exports to other countries where In- dians have taken abode. The demand for Indian traditional is spreading worldwide. Sugar drive from cane and honey, and to

- 27. Mithai & Namkeen Times 27 some extend jaggery are the world’s old- est sweeteners that has revolutionized the entire sweet culture. Traditional sweets or mithai is a craving that every person would like to indulge in and Indians are known to have something sweet post- lunch and dinner. This craving makes the mithais so special to us. Distribution of mithai means happy occasion and joyous times like birthday parties, engagements, weddings, birth, festivals, promotions, clearing examinations, recovery in health, and the list goes on. To celebrate people just seek tiniest opportunities to consume their favourite and wonderful delicacies. Hence, any news of mithai and sweets industry cannot go unnoticed. Therefore, read on to know what happened and why it is important to keep in touch with this food segment. The food regulator of India, Food Safety and Standards Authority of India (FSSAI) recently issued a directive wherein the lo- cal sweets shop have to mandatorily dis- play the ‘Date of Manufacture’ and ‘Best before Date’ on loose sweets sold in their shops effective from 1st June 2020. This move comes in the wake after sev- eral complaints were received from con- sumers over stale or expired sweets be- ing sold to them. Thus, coming in action, FSSAI have asked the sweet and mithai manufacturers to display the date of man- ufacture and best before date to ensure the customers receives freshly made products and can consume sweet items safe and sound and do not pose any health issues. With this transparency, FSSAI is sure that the consumers will purchase freshly made mithais and will not be misled by the mithai-makers to sell off stale sweets. Keeping the food safety and public inter- est in mind, a label on a mithai tray can be attached to display the date of manufac- ture that would safeguard the consumers buying sweets. Every product has its shelf life and the food regulator has issued sev- eral guidelines to be followed. FSSAI has issued a symbolic shelf life along with a suggestive logo for various types of sweets in a separate guidance note on milk products. As per the guidance note, traditional milk- based sweets are prepared from khoya, chhena (cheese curd), sugar and other ingredients such as maida, flavors and edible colors. Peda, burfi, milk cake, gu- lab jamun, rasgulla, ras-malai, and others have a limited shelf life. Sweets particu- larly those with milk products have a low shelf life and are more prone to get spoilt soon. Therefore sanitation and hygiene in their preparation and consumption within shelf life period are of utmost importance. Depending upon the nature of the sweets and its shelf life, FSSAI has classified the sweets as perishable sweets and highly perishable sweets - medium shelf life, long shelf life, and very long shelf life sweets. Based on the category, tags will be issued to all sweet shops and shopkeepers who should display the same, next to the sweet trays. And since there are issues of adul- teration and use of sub-standard products, the food regulator is taking efforts in this regard to ensure food safety of sweets by stakeholders including food businesses, consumers and regulatory authorities. FSSAI Joint Director (Regulatory Com- pliance) Parveen Jargar commented that, “FSSAI was receiving several complaints of expired / stale sweets being sold to consumers. And eating such sweets poses the human to dan- gerous health hazards. Because many people are unaware of the date of manufacture of these loose sweet items, unlike packaged ones wherein you have the information mentioned on the

- 28. Mithai & Namkeen Times 28 box, hence considering food safety and public interest, this step has been taken”. He further added that the Food Business Operators (FBOs) will decide the man- ufacturing date and best before date and they will indicate it, depending on the na- ture of sweets and local conditions. “FS- SAI has been pondering over this decision for a year. There were several discussions with various stakeholders about this mat- ter. And then ultimately, we arrived at this conclusion. For their convenience, we have made a guidance document that is available on our website and wherein they will receive all the information about food business operators and the procedure.” But to many mithaiwalas, this order by FSSAI seems impractical and difficult to implement. Impractical move because it is not possible to put up a label after every few hours depending on the sale of the products. Just, for example, jalebis and gulab jamun which are made in the morning and get sold out within couple of hours due to its high demand in the market. How is it practical to label best before and manufacturing date for every batch that is prepared for a particular day? Not too pleased with the order, delegates from Federation of Sweets and Namkeen Manufacturers (FSNM) met the FSSAI Joint Director (Regulatory Compliance) Parveen Jargar and Executive Direc- tor (Compliance Strategy/Training) Dr. Shobhit Jain had a long detailed meet- ing concerning this issue. The outcome of the meeting was that both parties agreed to work on some practical solutions. The industry will submit suggestions and FS- SAI and the government will consider it. Surely, the rules will be implemented as both the industry and governmental agen- cies will work together in this regard. Branded sweet retailers already follow the practice for their packaged products such as rasgulla and soan papdi. But the ratio of loose or unpackaged sweets made and sold is greater than the packaged ones. Hence this initiative by FSSAI is a de- batable one and after contemplation and talks, there could be an arrangement that would work for all. India has numerous traditional mithai shops that sell pack- aged as well as loose traditional sweet products. They sell dairy-based sweets prepared with khoya, desi ghee, and sug- ar/jaggery, they also prepared sweets with extended shelf lives. It becomes a com- plex matter when sweets having different shelf lives are kept in display counters for sale. Sometimes their shelf lives vary ac- cording to the climatic conditions. Here in monsoon sweets often gets spoilt due to moisture in air. Summers are also not good to keep milk burfis in a pro- longed period. Ingredients like dry fruits, edible colours etc... which are used in making mithai are found to be sub-stan- dard and for profit-making mithais are adulterated by preparing them in used re- fined oil, substitutes of sugar like saccha- rin is added and cheap flavours and dyes are mixed. Taking all this into consider- ation, a proper analysis should be worked out to make food healthy and free of con- tamination. Tagging the dates seems difficult on sweets as there are some provision stores or retailers who do not manufacture the sweets, but purchase them from whole- sale manufacturers and buy similar prod- ucts from various suppliers. In such cas- es, it is not feasible for the provision store owner to tag dates, as he is not the man- ufacturer nor has he any knowledge as to when it was prepared and how long it will last. For him it’s fresh when he received it and tries to sell off as soon as possible. Sometimes sweets can get spoilt at the hands of consumers. Mishandling of sweets with dirty or wet hands results in spoilage. Sweets bought and kept outside in humid climate or unclean containers also leads to the decay of sweets. In such circumstances, the customer cannot hold the manufacturer responsible for the hap- penings of the dates. Mithai & Namkeen Times took this op- portunity to speak to Firoz H. Naqvi, Director of Feder- ation of Sweets and Namkeen Manufacturers (FSNM) about this issue. Naqvi ex- pressed his view as: “We are with FSSAI, but some things are hard to implement. A lot of milk products have a limited shelf life, and some have a longer shelf life. Some shops have several products and it is difficult to put a label on each cate- gory because of varying shelf lives. The association was not consulted before pub- lishing the order. We put forward our con- cerns to the FSSAI and are trying to meet midway, where their concerns are met and ours too”. The FSNM represents interests of over 400 manufacturers of Indian sweets and namkeens including branded chains such as Haldiram’s and Bikanervala, among others. This federation represents the en- tire sweets & namkeen industry, both the manufacturing and allied sector. FSNM has been formed to improve this indus- try as it contributes to the accelerating growth of India’s GDP along with the other food sectors. Naqvi further added, “Some shops have several products and it is difficult to put a label on each category because certain items get over quickly within a day and thus several batches are prepared at in- tervals in a single day. The climatic con- ditions vary in the different parts of the country that affect the shelf life of these products. FSSAI should have approached us in this regard and we could have worked out a practical solution for the problem. We are eager to know how this can be implemented at the local levels in phases. As the mithai owners maintaining less than 5 stores in the city and in local areas will face problems and their busi- ness will be adversely impacted by this move. We always support FSSAI in their endeavour but this time, their sudden de- cision has taken the industry by surprise”. After speaking to the Director of FSNM, Mithai & Namkeen Times (MNT) went further to speak to few known personal- ities of mithai segment who have estab- lished their brand in this industry and asked for their opinion on this topic. From the Industry’s point of view After FSSAI mandated the date issue, the sweets manufacturers were completely surprised by this directive and wanted to convey their concerns to the authorities. They had a lot to say about this issue, and MNT came as the right media where they could openly share their thoughts on FSSAI’s rule of ‘best before’ and ‘date of manufacture’on loose sweets at the count- er. Excerpts from the renowned leaders from the industry share their views: Virendra Jain, President of FSNM said that consumers in India are well aware of the shelf life of sweets, just like how they know the shelf life of kachoris, samo- sas, food ordered from restaurants, etc. “We already

- 29. 29

- 30. Mithai & Namkeen Times 30 mention the shelf life of our products on the packaging in the manner of ‘good for (so-to-so) days’. There have been negli- gible complaints from customers on the sweets being sold after expiry from the reputed sweets shops. So we need to clar- ify our point of already taking into con- sideration the shelf life of our products.” The famous Dhiman Das, of K. C. Das Pvt Ltd hails from Kolkata. He has ex- pressed his concern over the date is- sues. According to Das, it is not only impractical but next to impossible to mention ‘date of manufacturing’ and ‘expiry date’ or ‘best before date’ on each tray every morning. “Most of the sweet shops display the name and price of sweets on each tray. The sweet shops mainly in Bengal are owned by people who earn their daily liv- ing from each day’s sales. There is hardly any staff to help them. The family mem- bers themselves run the shops. Shopkeep- ers can’t change the plates every morning or even write the ‘date of manufacturing’ and ‘expiry date’ by hand on almost 100 trays or more,” he told MNT. Yet another famous sweets producer, Pradeep Jain, MD of Jain Mishthan, Mumbai, expressed that new rule by FS- SAI is quite disturb- ing. Because, festival times are peak season where mithai is in great demand, one can only seeswarming crowd of people inside the outlets to buy sweets. In this commotion it is practically impossible to label every tray in the store as the trays keep on replenishing as they get over. Since the shop sells many varieties of sweets and various other products, label- ling or marking the trays seems totally unfeasible for the owner. Nowadays, consumers are well aware of the shelf life of the sweets being sold in shops and outlets like for example rasgul- la and ras-malai have a very short life. The mithai maker need not attach a date tag to it as all know that milk mithais do not last for more than two days. Practically put- ting the issue forth, based on a handful of complaints, there is no such requirement of a regulation received from FSSAI and applied across the country. Colloquially speaking, such types of complainants can be for any food items not related to sweets and mithai, then there is actually no need for such a directive which is highly unrea- sonable to implement it. Anil Saini from Bhanwarilal Mithai- wala, Indore appreciated the initiative taken by FSSAI. He said that FS- SAI wanted to ensure transparency and certainly there has been some problems that the sweet man- ufacturers have faced. Once transparency is in place, customers’ consumption ratio will in- crease. “Through this directive, the ones who contaminate the sweets or cheat the customers will either stop or mend their ways. Also, there are the ones who store it as stock and later sell it as fresh. They will not be able to do so, and all these activi- ties will not occur.” This will lead all the sweets manufacturers in the industry to be cautious and always ensure that fresh sweets are being sold to customers.” Upto some extent agreeing with FSSAI, N.S.R PrabhakarVarma from Sarvani Sweets, Vishakhapatnam - explained that FSSAI wants to put the coding ex- ercise in regards to the sale of loose sweets. It is like batch coding when in the pro- duction stage, they write a batch number on every portion that is produced. This batch number will also carry manufactur- ing date as well as ‘best before’ date. Varma further added, “It is observed that food products generally don’t expire so soon. Some carry their lives for years, they do have the best before dates but af- ter a time the food products starts to em- anate rancid smell, they lose their flavour and texture, crispiness as the case may be. Bengali sweets like rasgulla, gulab jamun, cham-cham have water content in it. On an open purchase and if stored for longer period, it turns sour. Packed tins, these sweets still have longer life due to preservatives added to it. These tin packs always carry best before date. I feel FSSAI wanted to introduce batch-based production and selling. Indi- rectly, they wanted to impact our produc- tion cycle, because this would force us to mark every batch at the back-end. But im- plementing this from June 1st, I think is a hasty step in a right direction.” Just like demonetization had affected the people all over the country, same way this date issue will affect everybody in the long-run. That’s because, not every- one understands the importance it has on mithai industry. Varma stated that the geographical conditions and climate also need to be considered as humidity in regions near the sea-side is much higher and India is a country with states that has various humidity levels because of their locations. “Based on the diversity of our country, having a common ‘Best Before’ is not possible. Then there are quality issues with the raw materials, not every material that goes in mithai-making is good. So no matter how hard we try to put a label on it, eventually, these labels will not be suit- able to the entire country. This will lead to large scale confusion in regard to the shelf life of food items.” Jay Sharma, from Gwalia Foods, Ahmedabad is of the view that retailers have many sweets and namkeen and thus not practi- cally possible to label every batch or lot prepared. “But we can mention the shelf life of these products so that consumers can make an informed choice while purchasing. The problem is that trays at the counter are refilled at timely intervals so every time putting a mark or label is not feasible. We are ready to mention the shelf life (should be consumed within 3 to 5 days) of the products.” He added mentioning best before and expiry dates on the trays seem a difficult task. And even if this is done, then consumers will only prefer the fresh batch prepared and that will become a problem for the retailer since the old batch will go in waste. Is there a mid-way solution to date is-

- 31. 31

- 32. Mithai & Namkeen Times 32 sue? Yes or No It seems that this move by FSSAI has not gone down too well with the sweet indus- try. The sweets manufacturers are equally concerned about their consumers’ safety and well-being. MNT wanted to know if a mid-way solution is possible or any sug- gestions the mithai makers would want to convey. MNT was glad to know their responses and suggestions which are put forth: Virendra Jain made his points clear. “We need to discuss the implementation of the expiry dates practically if at all; we need to put expiry dates on our products. It is practically impossible to label every loose sweet because our industry is both organized and majorly unorganized with small sweet shops all over the country. We (FSNM) as the face of the industry need to take care of their issues as well. Also, we can negotiate on the point that sealed packaging and preservatives are two ways to ensure that the products last till expiry. But when we are selling loose sweets, how we can guarantee the sweets expiry as it is up to the consumers, how they keep it. Like a lot of tin packaging, mentions an expiry of 3-6 months, but they don’t guarantee the expiry once the tin is opened. It is written to consume im- mediately once opened.” Pradeep Jain suggested that just like how price and quantity are mentioned on the tray of the sweets, it should also mention ‘good for two days’ or ‘to be consumed today only’. “Sweet manufac- turers should mention the shelf life along with the name and price of their products. We are equally concerned about consum- ers’ safety and health. Because, without customers’ support, we are nothing and so we cannot ignore their well-being,” replied Jain. Even Das echoed the same outlook. He said, “The best we can do is mention ‘consume within certain days’ along with the price and name of sweets.” Like ch- hena - based Bengali sweets have a shelf life of 24 – 72 hours. Khoya based sweets have a shelf life of almost 7 days, dry fruit-based sweets have a shelf life up to 15 days and so on”. Prabhakar stated that there is a midway but the problem is no one knows where to look for it or pinpoint the exact key. Those in North India will have a different perception on how sweets are manufac- tured to those who are based in Southern India. If the dates are standardized, then this will lead to a state of chaos for the manufacturers in this industry. Being flexible at this hour and to conclude the issue congenially seems the only remedy. On mentioning the dates becomes man- datory, the industry came expect miscom- munication amongst the manufacturers. As mithai industry is generally unorga- nized, there is no standard framework to assess the best before on the sweets. But if we look at the pharma industry, they are well organized and have a strict frame- work and laboratory assessment for the expiry dates which is adhered everywhere in India and abroad. Everything matters in the food industry, even a meagre tray matters. If the tray is not clean and has contaminants present on it, even though the sweet has a shelf life of 5 days will get spoil within two days. Ultimately, it is the retailer/wholesaler’s responsibility to ensure quality, hygiene and cleanliness. Quality has to be main- tained with full guaranty of the manufac- turer, retailer and shop owner. It is clear that FSSAI wants to bring the FMCG framework into the F&B industry. FMCG involves around all those packed goods that mention the expiry and manu- facture dates. They are trying to bring that framework into the F&B environment which is not possible. The producer can- not bring in the same frame of work with- out reliable RnD. Different places with their altitudes and climatic conditions have different impact on the products. Keeping in the above knowledge, FSSAI needs to reconsider their mandate decree and accordingly plan to take concrete de- cision helping the consumers and mithai industry at large. R&D - Need of the Hour India has technological equipment where products are made and packed 100% hu- man-hands-free stage. Still many man- ufacturers need to convert their way of preparation using minimal hands to maintain high level of hygiene that could benefit the sweets industry. Use of hi-tech machineries with artificial intelligence arms, will definitely increase the shelf lives of the products made. More RnD is required and test laboratories should be made easily available to certify the product’s life. Indian mithais are gaining global popularity among various cultural groups and regional places. Das alluded that as of now, there are no technological solutions regarding this. Even if India has some solutions, the cost shall be such that only a handful of branded sweet shops can afford it. Keeping in view the huge number of sweet shops mostly in Bengal in every nook and corner, aggregating to almost approximately 1 lakh or more who are not well-to-do at all, cannot avail of this technology because of the high cost. It should be noted that these shop owners are so poor that they cannot even afford to install a simple electronic cash register. Under such circumstances, there is an ob- vious need for RnD on this issue. As per Jain’s knowledge, “There is no such equipment but yes, there could be RnD done for technological machinery that will be useful for our industry and good-will of the customers”. On the other hand, Saini shared his plan of putting stickers on the sweets at the manufacturing site. And at the outlets and stores, a person could make use of the printer and print stickers to put it on the trays kept at the counter. He stressed that there should be RnD done for some technologically advanced machinery which would make things easier for the industry. “Just like how there are inter- national brands available in the market reaching our homes, same way we must try to achieve the similar goal. Our sweets should reach every household in the USA, European and Asian countries”. To conclude, consumption of mithai is an integral part of India’s meal and hence sweet manufacturers are constantly striv- ing to bring many innovation in their products. At the same time, they ensure that consumers’ health and safety is not neglected and quality is not compromised upon. It’s a wait and watch situation to see if FSSAI rule is implemented in the right manner or the sweet industry will seek to modify the edict!! Time is the decid- ing factor. Till then lets enjoy eating the mouth-watering mithais our country is famous for!

- 33. 33 20 years.... in Process Automation AAVEG Technology Pvt. Ltd. 9A, Electronic Complex Industrial Area, Indore 452010, M.P., INDIA +91 94250 56786, +91 97520 90253, info@aavegfoodmachine.com www.aaveghygiene.com www.aavegfoodmachine.com

- 34. Mithai & Namkeen Times 34 T he coronavirus (COVID-19) out- break is leading to widespread con- cern and is increasing economic hardship for all consumers, businesses and communities.RohitLalwani brings a special article of “Food Industry in COVID - 19 times” for his readers. Food Supplies 1. Whether the food supplies will be available during the period of complete lockdown? Answer: Yes, Ministry of Home Affairs vide order no 40-3/2020-DM-I(A) dated 26.03.2020 has issued directions in ref- erence to the complete lockdown, that supplies of essential commodities such as food supplies, medicines etc. will contin- ue to take place with proper precautions. Moreover the Central Government has also come up with ‘Pradhan MantriGa- reebKalyanYojana’ under which individ- uals benefited of subsidized public distri- bution will be receiving grains and other food supplies. Food Processing Industries 2. Whether the Ministry of Food Process- ing Industries has issued any Circular/ Notification/Order to address the pan- demic of COVID-19? Answer: Yes, the Ministry of Food Pro- cessing Industries vide Press Release ID: 1608340 dated 26.03.2020 has directed to a set-up of a Grievance Cell to ensure hassle free operations and uninterrupted

- 35. Mithai & Namkeen Times 35 India: Pandemic Legal Intelligence – Food Industry in COVID-19 times supply of essential for citizens. A Business Immunity Platform is set-up to help and support the businesses and investors. Essential Commodities Act, 1995 3. Under which law or rule, food is con- sidered as essential commodity? Answer: As per Section 2A of Essential Commodities Act, 1955 provides that Essential Commodity includes those enumerated under Schedule I of the Act. The Schedule to the Act include food as below; iii) Foodstuffs, including edible oilseeds and oils; Food & Retail Sector 4. Whether there is any notifications/cir- cular/order issued by the Government to include food shops and retailers under es- sential commodities? Answer: Yes, as per the Ministry of Home Affairs vide order no 40-3/2020-D dated 24.03.2020 has included shops, ration shops, which are dealing in food, grocer- ies, fruits and vegetables, and other food products also as essential commodities during the lockdown. Specific directions are also provided to district authorities to encourage home de- liveries in view of COVID-19. Food Retail Shops – Hygiene Aspect 5. Whether the employees, such as ca-

- 36. Mithai & Namkeen Times 36 shiers, cleaning personnel, in food retail shops are mandated to use on face masks, hand gloves and hand sanitizers? Answer: Per se, explicitly there is no guideline however these are advisable to prevent the employees who come in con- tact with customers and also to maintain hygiene during such testing time of infec tions. Further, hand sanitizers should be also kept to contain such outspread. E-Commerce 6. Whether there are any notification/cir- culars/orders to allow the ordering of food products through e-commerce operators? Answer: Yes, as per the Ministry of Home Affairs vide order no 40-3/2020- D dated 24.03.2020, the online essential commodities providers will be available during the lockdown period. However situations might arise in the cur- rent scenario that due to limited resources the delivery schedule might fluctuate. Distribution Of Essential Commoditi- ties 7. Whether Government has released any procedure/guidelines for distribution of essential commodities? Answer: Yes, the Ministry of Home Af- fairs vide order No. 40-3/2020-DM-I(A) dated 26.03.2020 issued a Standing Oper- ating Procedure (“SOP”) for maintaining supply of Essential Goods. Under the SOP government allows op- erations of suppliers of essential goods including restaurants for home delivery, warehouses and go downs for storage of essential goods, Transporters/drivers, etc. for transfer of essential goods from man- ufacturers to retailers. Import Clearance & Testing Labs 8. Whether Import clearance and Food Testing Labs are classified as essential services by FSSAI during the COVID-19? Answer: Yes, Food Safety Standards and Authority of India vide Press Release dat- ed 31.03.2020 has classified the import clearance of food items and functioning of notified food testing laboratories (in- cluding National Food Labs) under Es- sential Services during the COVID-19. It also directed all personnel who are as- signed charged to be required to be avail- able in office on all working days in order to facilitate the trade as well as ensure smoother operation of related services across the country. Fssai Compliance 9. Whether there is any specific procedur- al compliance requirements issued by the FSSAI for Food Business Operators? Answer: Yes, Food Safety Standards and Authority of India vide order no 15(6)2020/FLRS/RCD/FSSAI dated 31.03.2020 issued mandate procedure for application for FSSAI License/ Reg- istration through online mode on FLRS and possess the 17 digit valid application number. All the details shall be communicated to the commissioner of FSSAI by email by enclosing a FORM M with all the prescribe details which should be duly signed by the applicant. Food Business Operators 10. Whether there is any notification/cir- cular/order for First Business Operators to cover them under the ambit of FSS Act, 2006 during COVID-19? Answer: Yes, Food Safety Standards and Authority of India vide order no 15(6)2020/FLRS/RCD/FSSAI dated 31.03.2020 issued the directions to in- clude the operations of Food Business Operators (“FBO”) temporarily under Food Safety Standards Act, 2006. The directions by Food Safety Standards and Authority of India have also specified for the exclusions of Manufacturer’s from the relief provided in the aforesaid order for FBO’s. Time Limit By Fssai 11. Whether there is any notification/ circular/order specifying the time lim- it for FBOs to cease the business post COVID-19? Answer: Yes, Food Safety Standards and Authority of India vide order no 15(6)2020/FLRS/RCD/FSSAI dated 31.03.2020 issued directions specifying the time period for the FBO’s. The FBOs has to cease their operations within 30 days from the date lockdown ends. If the FBOs wants to continue their busi- ness then proper valid FSSAI license has to be applied by them. Fssai License Registeration 12. Whether there is any notification/cir- cular/order specifying the procedure for the processing of FSSAI License/ Regis- tration during and post lockdown? Answer: Yes, Food Safety Standards and Authority of India vide order no 15(6)2020/FLRS/RCD/FSSAI dated 31.03.2020 issued specific directions and detail procedure for the issuance of the License/ Registration during the time of lockdown and after pre-lockdown speci- fying the time period for the FBO’s. It also consist of detail directions for the inspection and issuance of License/ Reg- istration for the essential food and com- modities. Issues Awaiting Addressal During Covid -19 • Regarding Food & Beverages products (F&B), no guidelines or directions exists. Survival of start-ups in present pandemic era, dealing into F&B products has be- come a big concern due to clouds of con- fusions of lack of guidelines or directions for F&B products. • Guidelines issued by the Ministry of Affairs is silent on the scope of manu- facturers, suppliers and other food sellers during lockdown. • There is no clarity on the food ingredi- ents companies which manufacture and supply the basic ingredients for food products but they being incidental and ancillary should be treated at par food products. Future Challenges • As of now, disruptions are minimal as food supply has been adequate and mar- kets have been stable so far. However, we are already seeing challenges in terms of logistics bottlenecks (not being able to move food from point A to point B), and likely, there is less food of high-value commodities (i.e. fruits and vegetables) being produced. • Small-scale farmers and fishers also might face challenges accessing markets to sell their products or buy essential in- puts, or struggle due to higher food prices and limited purchasing power. • Shortages of labour could disrupt pro- duction and processing of food. • Food demand amongst major popula- tion in India is more linked to income, and hence loss of income-earning oppor- tunities could impact on its demand and consumption. This content is purely an academic analy- sis under “Legal intelligence series”. courtesy : www.amlegals.com AMLEGALS | Advocates & Advisors(A Law Firm in Ahmedabad)

- 37. 37